There are quite a number of different types of valves out there and the list can become rather daunting once you expand on solenoid valves. However, with solenoid valves we’ve simplified this for the primary types of valves that are out there as well as a brief overview of their functionality and how they operate.

Bi-Stable Solenoid Valve

A bi-stable solenoid valve is also known as latching solenoid valves. This type of valve takes the electrical current pulse to maintain a set position. This means once you’ve sent that electrical pulse the valve will retain the last position until such time when you send a pulse to switch positions. These valves are powered by magnets rather than a spring.

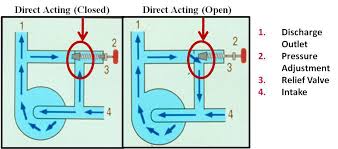

Direct Acting Solenoid Valve

Image source – Montgomery County, MD

Direct acting solenoid valves do not use a diaphragm. They do come in normally open and normally close.

For a normally closed version, when there is no power the plunger will block the orifice with the valve seal and a spring is forcing this closed position. When you apply power, it will create an electromagnetic field which will then allow the plunger to lift up and open the valve’s ports to allow media to flow.

The normally open version works just like this but the mechanics are just opposite. Generally, direct acting valves are used for low flow rates.

Indirect Acting Solenoid Valve

Indirect acting solenoid valves are also known as pilot operated or servo operated valves. These valves use the pressure differential of the media to open/close itself. They will require a minimum pressure differential of 0.5 bar.

For normally closed indirect acting valves, the ports are separated by the diaphragm. The diaphragm, also known as a rubber membrane, features a small hole so that the media can flow through the membrane to the upper chamber from the inlet port. When the indirect acting valve is normally closed the spring that supports from above the diaphragm is used so that the valve remains closed. The chamber that is above the diaphragm is designed so that there is a connection to a small channel to the low pressure port. This connection is blocked when the valve is closed by both the plunger and the seal. When the valve has energy applied to, then the pilot orifice [which is larger than the hole in the diaphragm] is opened and the pressure above the diaphragm begins to deplete and allow the diaphragm to be raised so that the media can flow in a unidirectional state from port to port.

For normally open versions it will have the same parts and works similarly but in the opposite manner.

Semi-Direct Acting Solenoid Valve

Semi direct acting solenoid valves, also called assisted-lift solenoids, are essentially a combination of direct and indirect acting valves. This combination allows them to work from little to no pressure but still handle a higher flow rate.

While they look quite like the indirect valves and feature a movable diaphragm that has a small orifice hole and pressure chambers, their main difference is that the solenoid’s plunger has been directly connected to the diaphragm. This allows for the plunger to directly lift the diaphragm to open the valve. During this time a second orifice was also opened by the plunger. It’s orifice has a larger diameter than the first one that is located in the diaphragm itself. This allows the pressure in the chamber above the diaphragm to decrease and allows for the diaphragm to be lifted by both the pressure difference and the plunger itself.

3-Way Direct Acting Valve

The 3-way direct acting valve features 3 ports that are able to do mixing or diverting. You can also find the 3-way direct acting valves with a feature called universal circuit function, this allows the valves to work in both directions. However, only two ports will be connected in each state.

3-Way Normally Open/Closed Solenoid Valves

When a 3-way valve is normally open it will feature 3 ports: cavity, body orifice, and stop port. Beyond the three ports there will be 2 orifices: the stop orifice and the body orifice. Between those two orifices one will always be open and that will allow for 2 flow paths. When there is no energy going to the valve, the plunger will be raised which in turn will seal off the stop orifice and allow for the body orifice to open and media to flow through the valve from the body orifice port and through to the cavity port. When there is energy to the coil then the plunger will be lowered and allowing for the body orifice to be sealed and opening up the stop orifice for the media to flow through the valve from the cavity port and out the stop port.

The 3-way normally closed solenoid valve will work with the same just with opposite mechanisms.

3-Way Directional Control Solenoid Valves

3-Way directional control solenoid valves feature 3 ports: cavity, body orifice, and a stop port. The valve also features 2 orifices which are the body and stop orifice. One of these two orifices will always be open and thus allows for 2 flow paths. When you energize the valve it will either raise or lower the plunger. When you raise the plunger it will seal the stop orifice and open the body orifice which will allow media to flow through the body of the valve. However, when the plunger is down it will seal off the body orifice and open the stop orifice to direct the media through.

Depending on your project, you might need one type of valve or another to satisfy your solenoid valve uses. Use some creativity to figure out the best use, or reach out to us for some guidance.