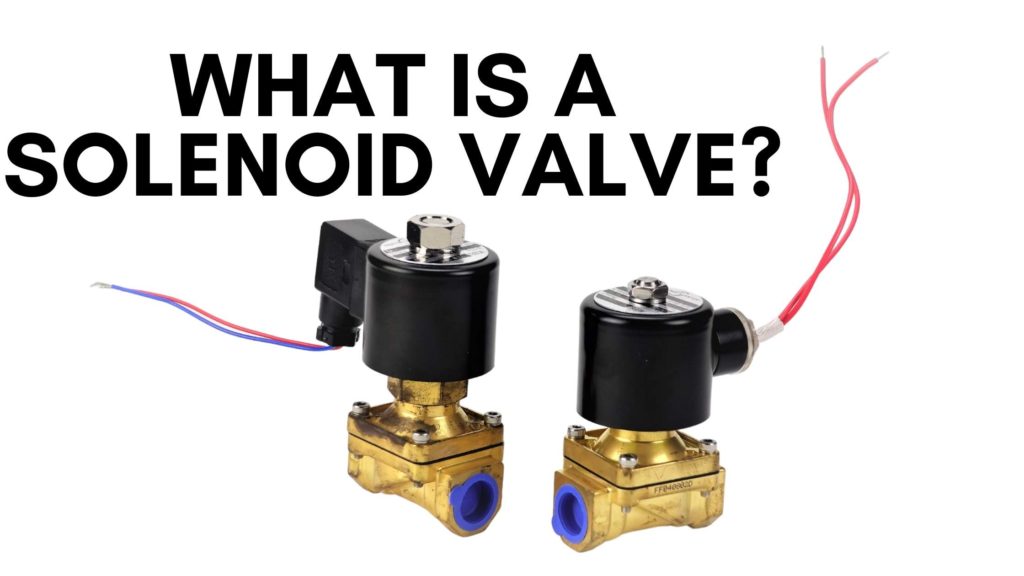

Simply speaking a solenoid valve is a type of valve that is able to be controlled electronically. While you can have dozens of types of valves, specifically a solenoid valve is a valve that has a solenoid used to open and close the flow of media.

A solenoid is an electric coil with a moveable plunger at its core. The default rest position will either close off the valve’s orifice or allow it to be open. This will depend on if your valve is normally open or normally closed.

When you energize the valve, an electric current runs through the coil and creates a magnetic field concentrated in that area. This magnetic field allows the valve to move the plunger up and down which will then allow for the opening or closing the orifice.

There are different types of solenoid valves, as previously mentioned. There is a distinctive difference between externally piloted, direct-acting valves, and internally piloted valves. You can also expand on the differences of the valves based on the number of port connections:

- if it modulates

- the number of flow paths

- the valve’s technical details itself

You can go further into differences based on the valve’s distinctive characteristics and what your job requires.

Such as valves can have a manual override function, handle LPG, work in a vacuum, handle back pressure, etc. A valve can be as unique as the project it is being installed into.

Valves can have many ports for fluid or gas paths. For example, a 2-way valve will have 2 ports and when the valve is open the ports are now connected and allow fluid or gas to flow between the ports. However, when the valve is closed then the two ports are no longer connected and the media flowing through the valve will stop.

Some valves come where their default state is open, known as normally open valves. When you have a valve like this it means the ports are connected when there is no energy and that once you apply energy to the valve the ports will then become isolated from one another until such time energy is removed.

The opposite of normally open is a normally closed valve. Those will be closed until power is applied and will then allow the valve to open connecting the two ports.

From there you can get into 3-way valves and other more intricate styles. 3-way solenoid valves are ones that feature 3 ports and the solenoid typically has one port that will connect to one of the other two ports which are generally a supply port and then an exhaust port.

While there are many ways to use a solenoid including one that acts directly on the main valve, you can also use a solenoid valve to actuate a larger valve. Those are solenoids that are combined with a pneumatically actuated valve. Often these are sold and packaged as a singular unit and referred to as a solenoid valve.

Pilot valves do not require as much power to control, but they are significantly slower. The other thing with pilot valves is that they generally will require full power at all times to open and stay open. However, direct acting valves often only need full power to open the valve and then the power consumption does reduce to maintain the valve’s open position.

Here is a great explainer video on how solenoid valves work…